Contact Coders > MINI CODER

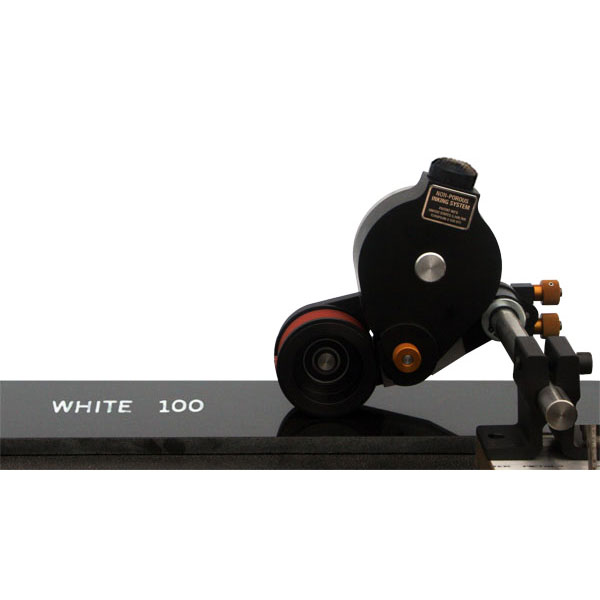

MINI CODER

Mini Coder Roller coder

Roller coder for coding and identifying products and packaging.

No Liquid ink, disposable inkrolls. Mini Coder offers a breakthrough in non-porous coding

Non-Porous Mini-Coders are the smallest of our fixed mounted Non-Porous coders.

Available in both side mount and top mount configurations, indexing and non-indexing models.

The inking system on these roll coders is completely enclosed to prevent solvent evaporation and unlike flexographic systems, there is no open well of ink. Remarkably, no maintenance is required during or at the end of each production shift which makes these printers the most trouble free on the market.

Precision engineered, remarkably versatile and reliable, this new system is revolutionizing the non-porous printing process.

MiniCoder Roller Coders is a contact coder, Top Mount configurations are used for printing on horizontal surfaces such as continuous web materials and side mount configurations are used primarily for printing on the sides of cartons or other vertical surfaces.

Euromps Srl Distributor for: Universal Stenciling & Marking Systems, Inc. is dedicated to the advancement of contact coding technology and through research and innovative designs, our products have remained one of the most efficient and cost effective methods of coding currently available.

Using MT Inkrolls for all coders :

You can install the coder even upside down, you can achieve printing speeds of up to 170 mt./min.

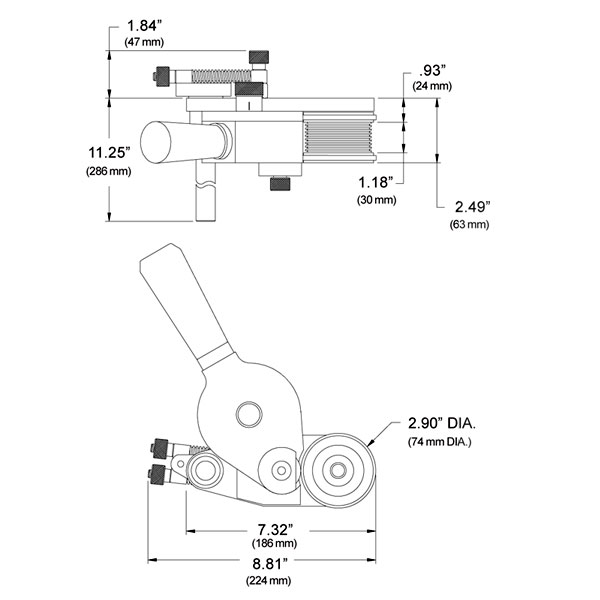

Printing Area: 25×230 mm.

System of Roll Coders :

Roller Coders are contact coders incorporates both an ink roll and an anilox roll in a tightly sealed aluminum housing which enables the use of inks that dry as fast as 2 seconds at 75 degree F. ambient temperatures.

The integrity of the inking system housing prevents solvent loss through evaporation and eliminates the maintenance demands normally associated with coding on non-porous surfaces. Our Non-Porous Inking System design is covered by international patents, making it unique in the world of non-porous coding.

Top Mount configurations are used for printing on horizontal surfaces such as continuous

web materials and side mount configurations are used primarily for printing on the sides of cartons or other vertical surfaces.

These coders are ideal for printing on plastic, metal, rubber, glass, waxed or varnished cartons.

How the Roll Coder works:

Roller coder for coding and identifying products is a type of coding system that uses a roller to apply ink or other marking material to a surface. Roll coders are often used in industrial applications to mark products or packaging with a variety of information, such as serial numbers, expiration dates, or batch codes.

The coding system of roll coder is typically based on contact coder.

Mini Coder coder works by rotating a roller that is coated with ink. The roller is then pressed against the surface to be marked, and the ink or marking material is transferred to the surface. The pattern of the ink or marking material on the surface represents the code that has been encoded.

Roll coders are a versatile and efficient way to mark products or packaging. They are inexpensive to purchase and operate, and they can be used to mark a wide variety of surfaces. Roll coders are also easy to maintain, and they can last for many years…..

Other printing areas are available :

HPNP-100 Series Hand Printers are the perfect solution for applying date codes, lot numbers and other product information on metals, glass, plastic, rubber and other non-porous materials: HPNP