Contact Coders > MIDSIZE ROLL CODERS

MIDSIZE ROLL CODERS

Universal Non-Porous Midsize Coders

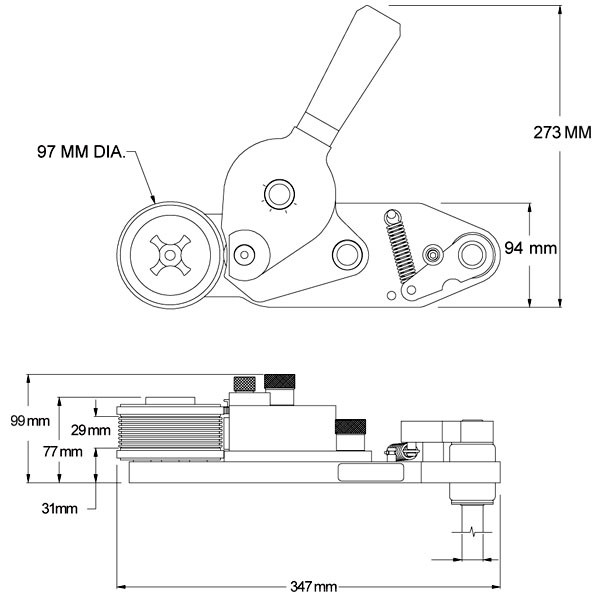

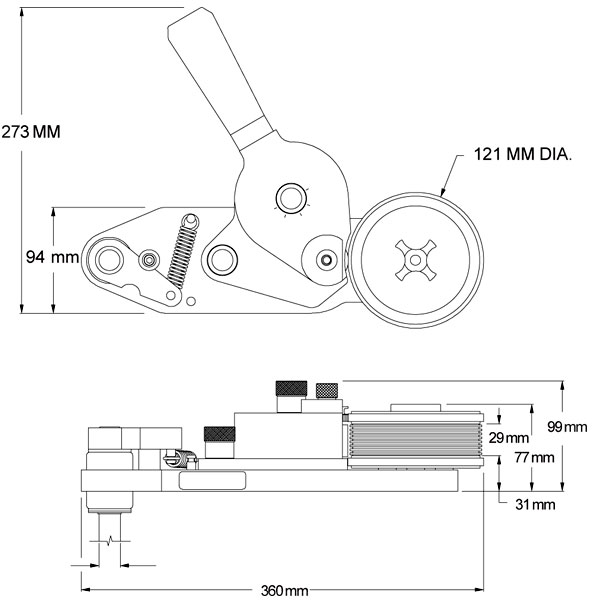

Midsize roll coder is a coding system. These roll coder are available with interchangeable 12″, 15″ and 18″ circumference print drums in both 1″ and 2″ print width models. Top mounted coders are ideal for continuous web printing on plastic films and side mounted models are particularly well suited for installation on carton sealing machinery. Indexing models feature a compression spring operated cam index mechanism for accurate indexing action even on short cartons or slow moving conveyor lines. The long frame design and extended deflection capabilities even permit in-line coding on the sides of metal or plastic drums.

Euromps Srl Distributor for: Universal Stenciling & Marking Systems, Inc.is dedicated to the advancement of contact coding technology and through research and innovative designs, our products have remained one of the most efficient and cost effective methods of coding currently available.

Using MT Inkrolls for all coders :

You can install the coder even upside down, you can achieve printing speeds of up to 170 mt./min

Midsize roll coder – coding system:

The Midsize Coders are precision machined entirely from aircraft grade aluminum alloys and stainless steel for extreme durability, no castings are used. Sealed ball bearings ensure smooth rotation of both the print drum and the anilox roll to minimize the drive force required for operation, a very important feature when printing on thin web materials. Universal’s line of Non-Porous MidSize Coders were designed to satisfy specific application requirements and supplement the capabilities of our other Non-Porous coders. Our patented non-porous inking system design enables the use of extremely fast drying alcohol base inks with drying times typically in the 2 second range at 75 Deg. F. ambient temperatures.

Exclusive Features

U.S. PATENT NO. 5,109,769 E.P. PATENT NO. 0508971

The mounting configurations are not interchangeable for these coders

so you must specify either right-hand or left-hand mounting configurations

and either top or side mount styles.

How the Roll Coder works:

A roll coder is a type of coding system that uses a roller to apply ink or other marking material to a surface. Roll coders are often used in industrial applications to mark products or packaging with a variety of information, such as serial numbers, expiration dates, or batch codes.

The coding system of roll coder is typically based on contact coder.

The roll coder works by rotating a roller that is coated with ink. The roller is then pressed against the surface to be marked, and the ink or marking material is transferred to the surface. The pattern of the ink or marking material on the surface represents the code that has been encoded.

Roll coders are a versatile and efficient way to mark products or packaging. They are inexpensive to purchase and operate, and they can be used to mark a wide variety of surfaces. Roll coders are also relatively easy to maintain, and they can last for many years…..

Here are some of the advantages of using a roll coder coding system:

Efficiency: Roll coders can mark a large number of products or packages quickly and easily.

Versatility: Roll coders can be used to mark a wide variety of surfaces.

Affordability: Roll coders are inexpensive to purchase and operate.

Ease of maintenance:

Roll coders are relatively easy to maintain.

Overall, roll coders are a versatile and efficient way to mark products or packaging. They are inexpensive to purchase and operate, and they can be used to mark a wide variety of surfaces.

Other printing areas are available :

HPNP-100 Series Hand Printers are the perfect solution for applying date codes, lot numbers and other product information on metals, glass, plastic, rubber and other non-porous materials: HPNP